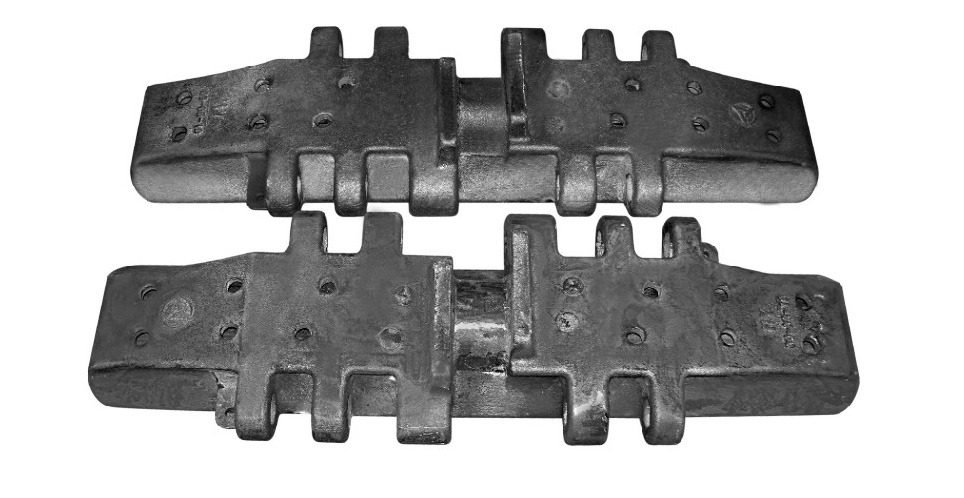

Front Idler Pulleys Undercarriage Parts For FUWA QUY50 Crawler Crane

Premium Idler Rollers for Crawler Crane Undercarriages

Maximize your crawler crane’s mobility and load-bearing capacity with FUWA heavy-duty track shoes. Engineered for mining, construction, and heavy lifting operations, our Guide Wheel deliver unmatched durability on rugged terrains.

In Stock & Ready to Ship |

In Stock & Ready to Ship |  Custom Sizes/Designs Accepted |

Custom Sizes/Designs Accepted |  1-Piece MOQ

1-Piece MOQ

Key Product Features

►Superior Material Composition

High-performance alloy steel options: 35SiMn, 35SiMnMo, 28CrMnMo

Heat-treated surfaces for wear resistance & impact absorption

Corrosion protection for extended service life

► Reliable Performance Guarantee

2500 working hours or 1-year warranty (whichever comes first)

Rigorous QA testing compliant with ISO/CE standards

Compatible with Liebherr, Caterpillar, Hitachi, Zoomlion SANY, FUWA, XCMG and major crane brands

►Fast-Track Order Fulfillment

7-20 days lead time (most parts in stock at Shanghai/Dalian ports)

Export-ready plywood box packaging for damage-proof transit

Flexible logistics: EXW, FOB, CFR, CIF terms

Technical Specifications

| Parameter |

Details |

| Material Options |

35SiMn / 35SiMnMo / 28CrMnMo |

| Surface Treatment |

Shot blasting + Anti-rust coating |

| Load Capacity |

Customizable per OEM requirements |

| Applications |

Mining sites, port logistics, bridge engineering, oilfield operations |

Why Choose SHENYANG WINNINGS MACHINERY TRADING CO. LTD?

►Precision Manufacturing

CNC-machined bolt holes for perfect alignment

Interchangeable design reduces downtime during replacements

►OEM/ODM Capabilities

Submit drawings for custom-idler rollers solutions

Bulk order discounts available

► Global Supply Expertise

10+ years serving EPC contractors and crane rental companies

T/T, Western Union, and secure payment gateways accepted

Idler rollers /Idler pulley Model:

Idler rollers /Idler pulley Model:

| HITACHI |

| KH100 |

KH125 |

KH150 |

KH180 |

KH230 |

KH250 |

KH300 |

KH500 |

| KH700 |

CX300 |

CX500 |

CX550 |

CX650 |

CX700 |

CX900 |

PD7 |

| PD100 |

|

|

|

|

|

|

|

| SUMITOMO |

| SC350 |

SC400 |

SC500 |

SC550 |

SC650 |

SC700 |

SC800 |

SC100 |

| SC1500 |

LS13RH |

LS78RM |

LS78RH5 |

LS78RHD5 |

LS98 |

LS108RM |

LS110C |

| LS118RH3 |

LS118RH5 |

LS120RH5 |

LS138H |

LS138RH5 |

LS208H |

LS218H |

LS218RH5 |

| LS238RH2 |

LS238RH3 |

LS238RH5 |

LS458HD |

LS468HD |

LS518 |

LS528 |

SD205 |

| SD307 |

SD407 |

SD610 |

|

|

|

|

|

| HITACHI SUMITOMO |

| SCX300 |

SCX400 |

SCX500 |

SCX700 |

SCX800 |

SCX900 |

SCX1200 |

SCX1500 |

| SCX2000 |

SCX2500 |

SCX2600 |

SCX2800 |

|

|

|

|

| DEMAG |

| CC1000 |

CC1200 |

CC1400 |

CC1500 |

CC1800 |

CC2000 |

CC2200 |

CC2500 |

| CC2800 |

CC4000 |

CC5800 |

CC6800 |

|

|

|

|

| FUWA |

| QUY35 |

QUY50 |

QUY70 |

QUY80 |

QUY90 |

QUY100 |

QUY120 |

QUY150 |

| QUY250 |

QUY320 |

QUY400 |

QUY500 |

QUY650 |

QUY750 |

QUY1250 |

|

| SANY |

| SCC500 |

SCC550 |

SCC600 |

SCC700 |

SCC750 |

SCC800 |

SCC1000 |

SCC1250 |

| SCC1500 |

SCC1800 |

SCC2600 |

SCC3000 |

SCC4000 |

SCC5000 |

SCC6500 |

SCC7500 |

| SCC8100 |

SCC8200 |

SCC8300 |

SCC10000 |

SCC16000 |

|

|

|

| ZOOMLION |

| QUY35 |

QUY50 |

QUY70 |

QUY80 |

QUY90 |

QUY100 |

QUY120 |

QUY130 |

| QUY150 |

QUY180 |

QUY250 |

QUY320 |

QUY400 |

QUY500 |

QUY650 |

QUY750 |

| QUY1250 |

|

|

|

|

|

|

|

| XCMG |

| QUY 38-350 TON |

|

|

|

|

|

|

Related Products:

FAQ – Top 5 Customer Questions

1. What Products Do You Supply?

We specialize in full-range crawler crane undercarriage components:

Track Shoes/Plates | Drive Sprockets | Idlers

Upper/Lower Rollers | Bottom Rollers | Carrier Wheels

Custom OEM parts accepted via drawings or samples.

2. Why Choose Us Over Competitors?

Factory-Direct Pricing: 10+ years of export expertise, 15-30% cheaper than traders.

Zero Minimums: Order 1 piece or 1,000+ with equal priority.

3-Stage Quality Assurance:

▶ Raw Material Spectrometry Testing

▶ Pre-Production Sample Approval

▶ 100% Final Inspection + Anti-Rust Packaging

3. I Only Know My Crane Model – No Part Number. Help!

No problem! We maintain a global machine database for accurate matching:

Send photos of old parts (with key dimensions marked)

Provide equipment nameplate details (Model/Serial No.)

Connect via WhatsApp/Email for real-time technical support

4. How Do You Guarantee Quality?

Military-Spec Inspection Process:

Raw Material Check → Prototype CMM Measurement → Batch Hardness Test → 72-Hr Salt Spray Test → Dynamic Balance Certification

Includes Material Test Reports & ISO 9001 Compliance

5. What’s Your Warranty Policy?

Industry-Leading Coverage: 1 year or 2,500 working hours (whichever comes first).

Emergency Support: 48-hour spare parts dispatch for Asia/Middle East/Africa regions.

![]() In Stock & Ready to Ship |

In Stock & Ready to Ship | ![]() Custom Sizes/Designs Accepted |

Custom Sizes/Designs Accepted | ![]() 1-Piece MOQ

1-Piece MOQ