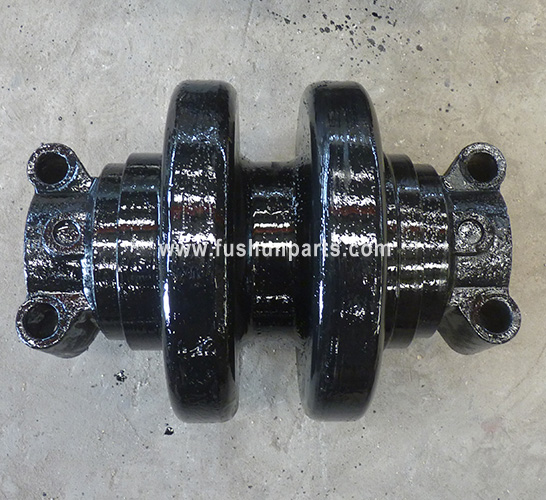

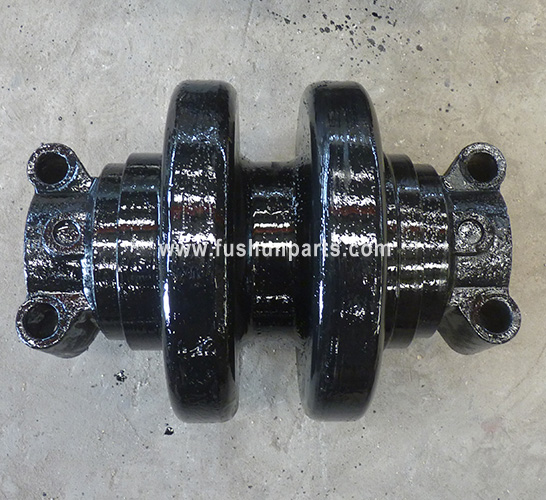

Undercarriage Parts Track Rollers for MONITOWOC Crawler Cranes

Premium Sprockets Rollers for Crawler Crane Undercarriages

Maximize your crawler crane’s mobility and load-bearing capacity with MONITOWOC heavy-duty track rollers. Engineered for mining, construction, and heavy lifting operations, our lower rollers deliver unmatched durability on rugged terrains.

In Stock & Ready to Ship |

In Stock & Ready to Ship |  Custom Sizes/Designs Accepted |

Custom Sizes/Designs Accepted |  1-Piece MOQ

1-Piece MOQ

Key Product Features

►Superior Material Composition

High-performance alloy steel options: 35SiMn, 35SiMnMo, 28CrMnMo

Heat-treated surfaces for wear resistance & impact absorption

Corrosion protection for extended service life

► Reliable Performance Guarantee

2500 working hours or 1-year warranty (whichever comes first)

Rigorous QA testing compliant with ISO/CE standards

Compatible with Liebherr, Caterpillar, Hitachi, Zoomlion SANY, FUWA, XCMG and major crane brands

►Fast-Track Order Fulfillment

7-20 days lead time (most parts in stock at Shanghai/Dalian ports)

Export-ready plywood box packaging for damage-proof transit

Flexible logistics: EXW, FOB, CFR, CIF terms

Technical Specifications

| Parameter |

Details |

| Material Options |

35SiMn / 35SiMnMo / 28CrMnMo |

| Surface Treatment |

Shot blasting + Anti-rust coating |

| Load Capacity |

Customizable per OEM requirements |

| Applications |

Mining sites, port logistics, bridge engineering, oilfield operations |

Why Choose SHENYANG WINNINGS MACHINERY TRADING CO. LTD?

►Precision Manufacturing

CNC-machined bolt holes for perfect alignment

Interchangeable design reduces downtime during replacements

►OEM/ODM Capabilities

Submit drawings for custom-idler rollers solutions

Bulk order discounts available

► Global Supply Expertise

10+ years serving EPC contractors and crane rental companies

T/T, Western Union, and secure payment gateways accepted

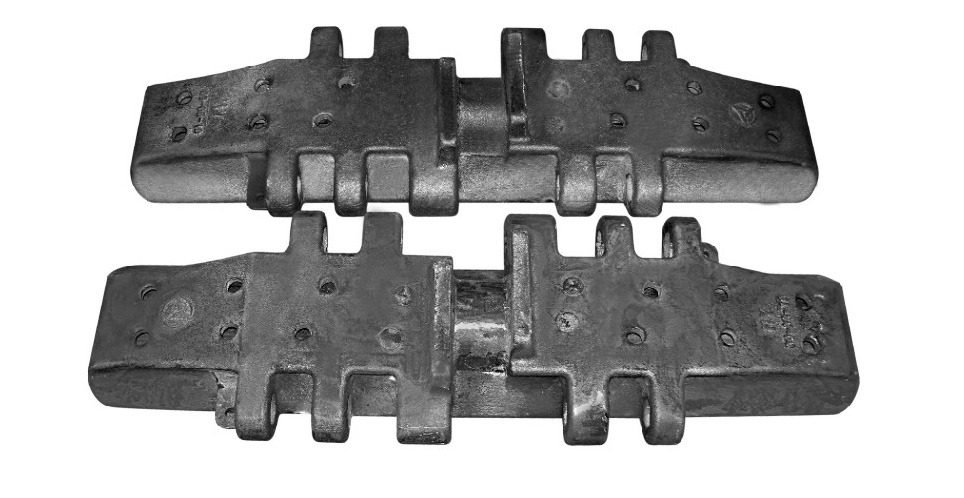

As a professional crawler crane undercarriage parts supplier, we provide upper and lower rollers, track shoes, idlers and sprockets. Most of those parts are often in our stock. We accept OEM or drawing, welcome to contact us, looking forward to cooperating with you.

FUWA crane track rollers:

MANITOWOC crane track rollers:

MANITOWOC crane track rollers:

SUMMITOMO crane track rollers:

SUMMITOMO crane track rollers:

KOBELCO crane track rollers:

KOBELCO crane track rollers:

Crane Undercarriage Parts Model:

Crane Undercarriage Parts Model:

| HITACHI |

| KH100 |

KH125 |

KH150 |

KH180 |

KH230 |

KH250 |

KH300 |

KH500 |

| KH700 |

CX300 |

CX500 |

CX550 |

CX650 |

CX700 |

CX900 |

PD7 |

| PD100 |

|

|

|

|

|

|

|

| SUMITOMO |

| SC350 |

SC400 |

SC500 |

SC550 |

SC650 |

SC700 |

SC800 |

SC100 |

| SC1500 |

LS13RH |

LS78RM |

LS78RH5 |

LS78RHD5 |

LS98 |

LS108RM |

LS110C |

| LS118RH3 |

LS118RH5 |

LS120RH5 |

LS138H |

LS138RH5 |

LS208H |

LS218H |

LS218RH5 |

| LS238RH2 |

LS238RH3 |

LS238RH5 |

LS458HD |

LS468HD |

LS518 |

LS528 |

SD205 |

| SD307 |

SD407 |

SD610 |

|

|

|

|

|

| HITACHI SUMITOMO |

| SCX300 |

SCX400 |

SCX500 |

SCX700 |

SCX800 |

SCX900 |

SCX1200 |

SCX1500 |

| SCX2000 |

SCX2500 |

SCX2600 |

SCX2800 |

|

|

|

|

| FUWA |

| QUY35 |

QUY50 |

QUY70 |

QUY80 |

QUY90 |

QUY100 |

QUY120 |

QUY150 |

| QUY250 |

QUY320 |

QUY400 |

QUY500 |

QUY650 |

QUY750 |

QUY1250 |

|

| SANY |

| SCC500 |

SCC550 |

SCC600 |

SCC700 |

SCC750 |

SCC800 |

SCC1000 |

SCC1250 |

| SCC1500 |

SCC1800 |

SCC2600 |

SCC3000 |

SCC4000 |

SCC5000 |

SCC6500 |

SCC7500 |

| SCC8100 |

SCC8200 |

SCC8300 |

SCC10000 |

SCC16000 |

|

|

|

| ZOOMLION |

| QUY35 |

QUY50 |

QUY70 |

QUY80 |

QUY90 |

QUY100 |

QUY120 |

QUY130 |

| QUY150 |

QUY180 |

QUY250 |

QUY320 |

QUY400 |

QUY500 |

QUY650 |

QUY750 |

| QUY1250 |

|

|

|

|

|

|

|

| XCMG |

| QUY 38-350 TON |

|

|

|

|

|

|

Related Products:

FAQ – Top 5 Customer Questions

1. What Products Do You Supply?

We specialize in full-range crawler crane undercarriage components:

Track Shoes/Plates | Drive Sprockets | Idlers

Upper/Lower Rollers | Bottom Rollers | Carrier Wheels

Custom OEM parts accepted via drawings or samples.

2. Why Choose Us Over Competitors?

Factory-Direct Pricing: 10+ years of export expertise, 15-30% cheaper than traders.

Zero Minimums: Order 1 piece or 1,000+ with equal priority.

3-Stage Quality Assurance:

▶ Raw Material Spectrometry Testing

▶ Pre-Production Sample Approval

▶ 100% Final Inspection + Anti-Rust Packaging

3. I Only Know My Crane Model – No Part Number. Help!

No problem! We maintain a global machine database for accurate matching:

Send photos of old parts (with key dimensions marked)

Provide equipment nameplate details (Model/Serial No.)

Connect via WhatsApp/Email for real-time technical support

4. How Do You Guarantee Quality?

Military-Spec Inspection Process:

Raw Material Check → Prototype CMM Measurement → Batch Hardness Test → 72-Hr Salt Spray Test → Dynamic Balance Certification

Includes Material Test Reports & ISO 9001 Compliance

5. What’s Your Warranty Policy?

Industry-Leading Coverage: 1 year or 2,500 working hours (whichever comes first).

Emergency Support: 48-hour spare parts dispatch for Asia/Middle East/Africa regions.

![]() In Stock & Ready to Ship |

In Stock & Ready to Ship | ![]() Custom Sizes/Designs Accepted |

Custom Sizes/Designs Accepted | ![]() 1-Piece MOQ

1-Piece MOQ